Benefits of Using Diamond Tools for Stone Cutting

Share

Diamond tools create clean, smooth cuts when cutting rough and hard stone, such as granite, marble, and quartzite, due to the diamond's hardness, abrasiveness, durability, and precision.

Diamond Saws and Blades: Essential For Cutting Stone

Enabling precise and accurate cuts, diamond saw blades are essential for stone fabrication, from the most demanding cutting applications to everyday repair and construction.

- Accuracy: A rail saw is designed to make precise cuts, and a high-quality saw can ensure that your cuts are accurate and uniform.

- Efficiency: A high-quality rail saw can cut through stone slabs more quickly, saving time and allowing you to complete more jobs in less time.

- Safety: A well-maintained saw with a sharp blade can reduce the risk of accidents or injuries when using a dull or damaged saw.

- Durability: Investing in a high-quality rail saw can withstand heavy use and last for years, reducing the need for costly repairs or replacements.

Diamond cutting blades are typically made using sintering, which involves combining synthetic diamonds with a metal powder, such as nickel, and pressing the mixture under high pressure and temperature to form a solid, diamond-studded segment or rim.

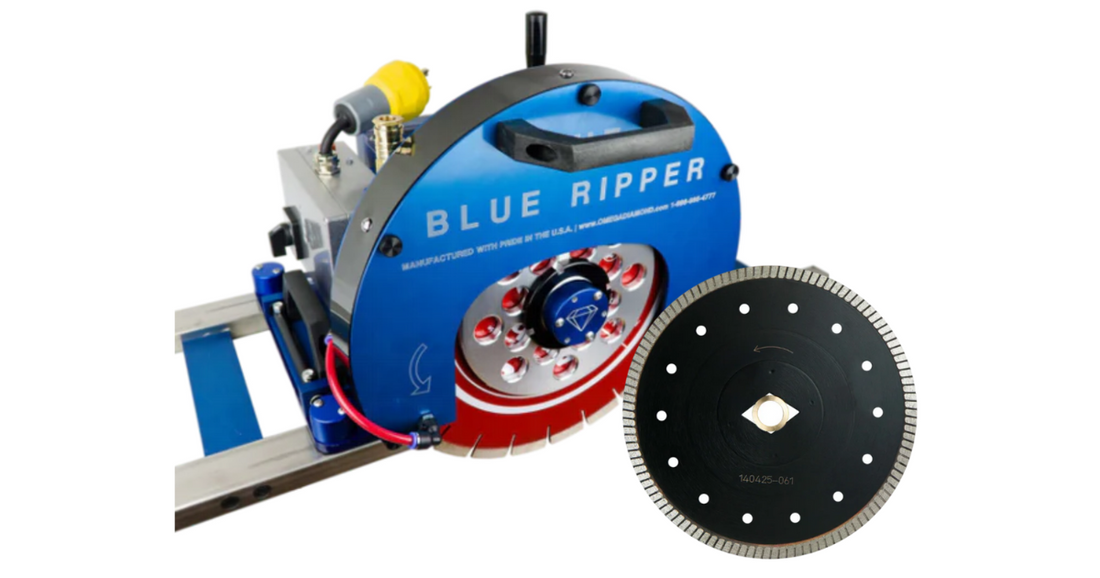

Blue Ripper Rail Saw

The portable Blue Ripper Sr Rail Saw features a powerful motor and a 14-inch diamond blade, which can easily cut through stone and other hard materials. The 3-horsepower model is air-cooled, while the 5-horsepower model is water-cooled, which helps reduce heat buildup and extend the blade's life.

Low Horsepower Diamond Blades

Low-horsepower diamond saw blades are designed for rail, track, and small bridge saws with a 10HP or less motor. They typically have an outside diameter of 13 7/8", which allows them to fit on the Blue Ripper Rail Saw and inside other saws with a 14" blade housing, such as the Achilli TSA 3 HP Portable Track Saw.

Continuous Rim Blades: These blades have a smooth, continuous edge with no gaps, making them ideal for precise cuts in softer stones such as marble, travertine, and limestone.

Segmented Blades: These blades have a segmented rim with gaps between each segment, making them ideal for cutting harder materials such as granite, sandstone, and bluestone.

Turbo Blades: These blades have a serrated edge ideal for use on angle grinders and are available in continuous and segmented rim designs.

Bridge Saw Blades: These blades are designed for use with large, stationary bridge saws and are ideal for cutting large slabs of stone. Primarily used in the stone countertop industry.

Sintered Blades: The sintering process is what is used to create the diamond segments. These segments are then attached to a steel core to create a segmented blade.

Electroplated Blades: These blades are made by coating diamond particles onto a metal core using electroplating. They are ideal for cutting softer materials such as marble, ceramic tiles, and glass.

Silent Blades: These blades are designed to reduce noise levels. The two outer layers are normally steel, while the inner layer is copper or another soft metal. Silent-core blades are wet cutting only.

Tait Sales and Consulting

No matter the project, a high-performance blade is essential to complete intricate cuts safely and quickly. With heightened speed and precision, these blades are ideal for working with various stone types in any application. Tait Sales and Consulting is the go-to place for the highest-quality diamond saw blades and fabrication accessories. Check out our website and call TSC today!