Weha

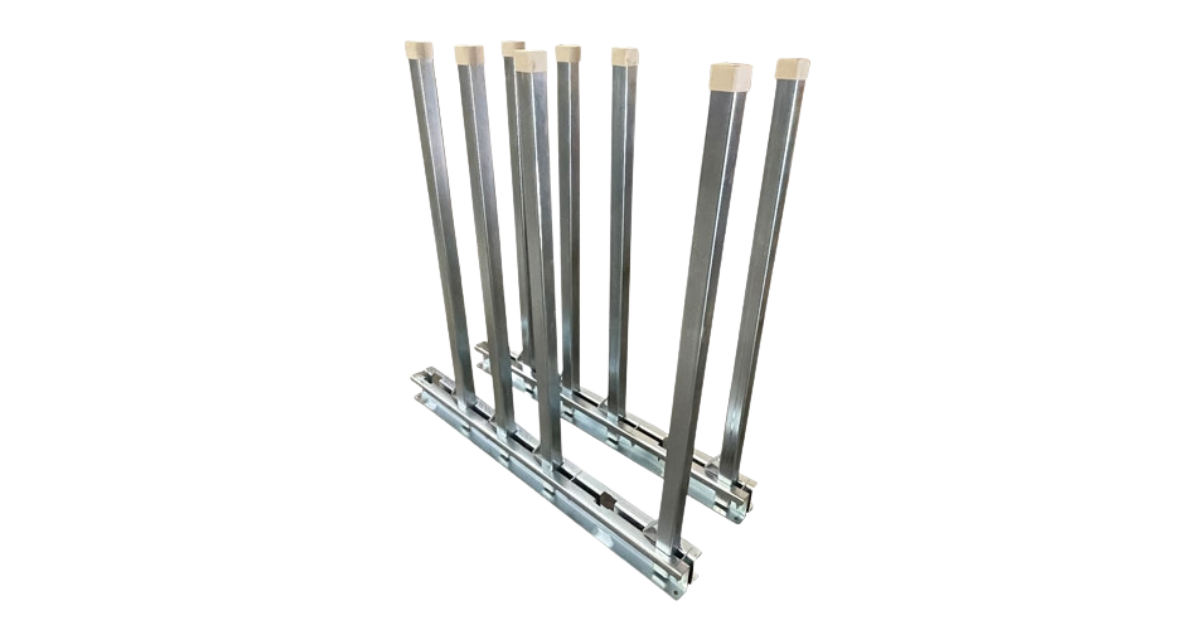

Weha 5′ Buffalo Slab Rack

Weha 5′ Buffalo Slab Rack

Part #

SKU:149379

Couldn't load pickup availability

Weha Buffalo Bundle Slab Storage Rack 5′ long with fully Hot Dipped Galvanized. World Patent Design

Weha Buffalo Slab Bundle Storage Racks are the latest technology in vertical stone storage.

The Weha Buffalo Slab Racks are rated for 11,500 lbs per set of poles.

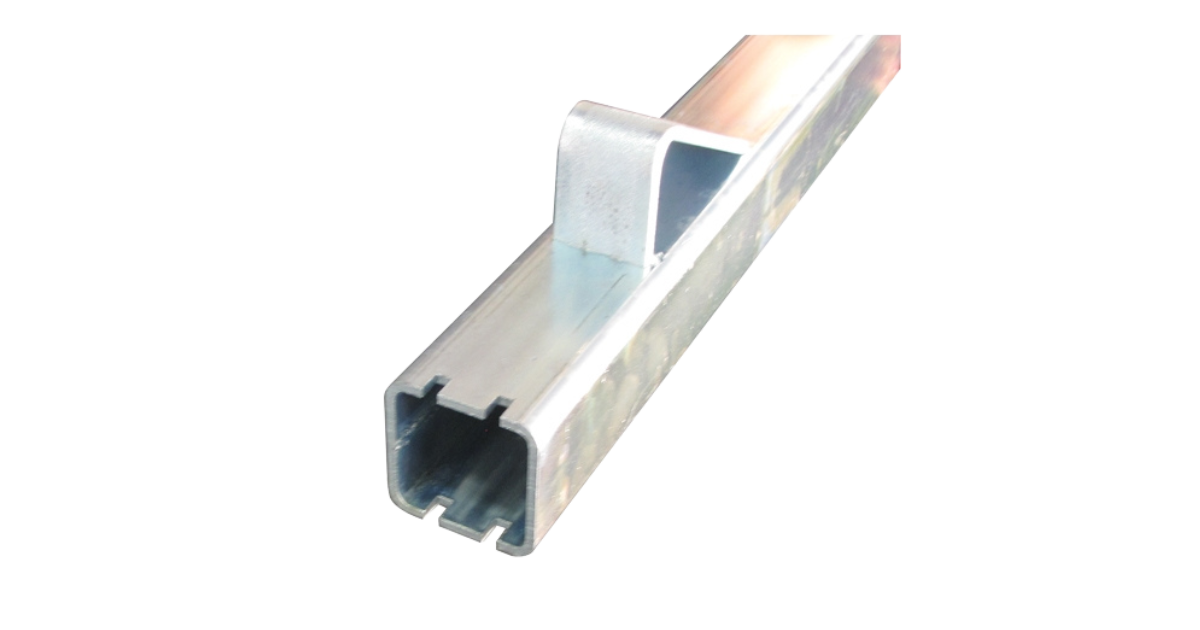

Weha Buffalo Bundle Slab Storage rack design has created a 6 point post touch locking system. While other slab rack bases touch the pole in 1 or 2 places, the Weha Buffalo Slab Rack base creates 6 different pressure points on the post. This design increases the metal to metal contact from a standard 4 1/2″ to over 9 1/2″, doubling the surface contact.

This world patented design offers safest and strongest way of storing stone slabs, including bundles of granite, marble, engineered stone, quartz, quartzite and all natural stone.

Weha special patent multi locking post to base design offers the most surface contact between base and post than any other slab rack system on the market. This design increases the structural strength by 57%. This translates into a greater weight capacity, with full confidence and worry free storing of full bundles of granite and marble in both 2cm and 3cm stone.

Why Galvanization is Better than Painted A Frames:

1. Most economical: Galvanized steel is often the least expensive initial choice. As other labour intensive coatings have risen in rates, galvanizing has maintained a consistent price-point. Moreover, it lasts longer and requires less maintenance, making it the most cost effective, long-term option.

2. Maintenance-free: Galvanizing provides maintenance-free corrosion protection, unlike other protective coatings. This mitigates long-term costs, hassles and disruptions to production.

3. Longest lifespan: Galvanized coatings on typical structural members have a life expectancy in excess of 100 years.

4. Most durable: A galvanized coating has a unique metallurgical structure, providing outstanding resistance to damage during transport, erection and service.

5. Most reliable performance: Galvanizing is carried out to ASTM A123 and standard, minimum coating thicknesses are applied. Coating life and performance are reliable and predictable as it’s performance is based on the known corrosion rate of zinc. Galvanized steel provides a thick, complete and easily inspected coating.

6. Most protection: Galvanizing protects every part of a structure, including recesses, sharp corners and inaccessible areas. Galvanized coatings also provide cathodic or sacrificial protection to small areas of steel that are exposed due to damage. Unlike other coating options, small damaged areas are automatically protected and don’t require touch-ups due to zinc’s sacrificial nature.

Share