A Detailed Guide to Safe Lifting With Vacuum Lifters

Share

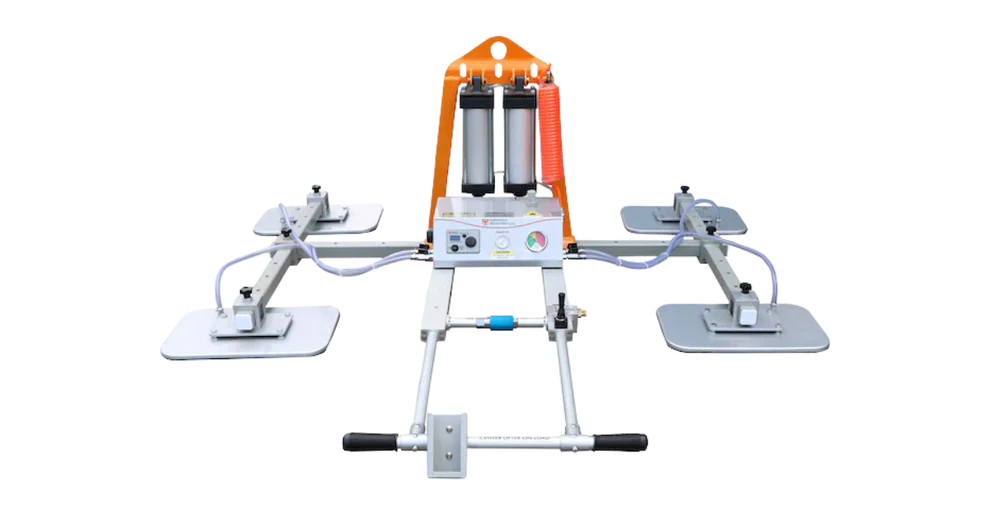

Lifting heavy materials like glass or stone can be tough and dangerous without the right tools. Vacuum lifters make this job easier and safer. These machines use suction to lift and move heavy items like stone slabs or glass panels. This reduces the strain on workers and helps prevent accidents. Whether you're working with glass sheets or large stone pieces, vacuum lifters offer a simple solution for safer lifting.

If you're tired of struggling with heavy loads or risking injury, vacuum lifters and glass lifters are great tools to consider. Let’s explore how these machines work and why they are useful for safe lifting.

Understanding Vacuum Lifters

Vacuum lifters use suction to lift heavy materials. Suction cups attach to the material's surface, creating a strong vacuum seal. This seal lets the machine lift and move the material without manual force.

These machines are ideal for industries that handle fragile or large materials, such as glass and stone. Glass lifters, for example, are specifically designed to handle large glass panels without scratching or breaking them. Vacuum lifters come in different sizes and can be used for various construction, manufacturing, and stone-handling tasks.

Benefits of Using Vacuum Lifters

1. Reduced Manual Lifting

A major benefit of vacuum lifters is eliminating the need for heavy manual lifting. Lifting large pieces of stone or glass by hand can strain your back and cause injuries. With a vacuum lifter, the machine does the heavy lifting for you. This makes the job easier and reduces the risk of workplace accidents.

2. Increased Efficiency in Stone Handling

Handling large stone slabs becomes much faster and easier when using vacuum lifters. The machine grips the stone securely, allowing you to move it smoothly from one place to another. This speeds up the process, so you can complete tasks more quickly and efficiently. This can save a lot of time and effort in construction or manufacturing.

3. Suitable for Different Tasks

Vacuum lifters aren’t just for lifting one type of material. They can handle different tasks, including lifting stone, glass, or metal sheets. This versatility makes them a great tool for various industries. Whether you’re lifting fragile glass panels or heavy stone slabs, these machines offer reliable support.

4. Adjustable Settings

Most vacuum lifters come with adjustable settings, which make them even more useful. You can adjust the suction power to match the weight and size of the material you’re handling. This flexibility allows you to safely lift different materials without worrying about damage or accidents.

Pre-Lift Safety Checklist

Before using a vacuum lifter or glass lifter to move heavy materials, it’s important to ensure that everything is safe and ready. Here’s a simple checklist to ensure your lifting operation goes smoothly and safely.

1. Choosing the Right Vacuum Lifter

The first step is to pick the right vacuum lifter for the job. Different lifters are designed for different materials and weights. Make sure the lifter you choose can handle the size and weight of the material you need to lift. For example, glass lifters are best for fragile glass panels, while larger vacuum lifters are better for heavy stone slabs. Always check the lifter's weight limit before you start.

2. Workplace Safety Assessment

Before you begin, assess the area where the lift will happen. Check for any obstacles that could be in the way, such as uneven floors or objects on the ground. Make sure there is enough space for the vacuum lifter to move freely. If there are workers nearby, ensure they are aware of the operation and standing at a safe distance. Keep the work area clear of unnecessary items to reduce the risk of accidents.

3. Load Inspection

Before lifting the material, inspect the load carefully. Make sure there are no cracks, chips, or other damage that could affect the lifting process. If you’re lifting glass, ensure the surface is clean and smooth to allow the suction cups to form a secure seal. Check that the surface is stable and debris-free for stone or other heavy materials. A quick inspection can prevent damage to the material and avoid accidents during the lift.

4. Operator Training

Make sure the person operating the vacuum lifter has proper training. Vacuum lifters seem easy to use but still require careful handling. The operator should know how to adjust the suction settings, move the lifter smoothly, and handle emergencies. Regular training and refresher courses help ensure that operators stay updated on safety practices and know how to use the equipment correctly.

Safe Lifting Techniques with Vacuum Lifters

Vacuum lifters make moving heavy items like glass or stone easier and safer, but you must still follow the right steps. Here's a simple guide to safe lifting with vacuum lifters.

1. Pre-Lift Checks

Before you lift anything, check the vacuum lifter and the material. Make sure the suction cups are clean and undamaged. Ensure the lifter can handle the weight of the material you're lifting. Check that the material's surface, whether glass or stone, is clean and smooth so the suction works properly. These quick checks help prevent accidents.

2. Lifting Procedures

When you’re ready to lift, position the vacuum lifter right above the center of the load. Turn on the vacuum to create a strong grip on the material. Once you're sure the material is securely attached, begin lifting slowly. Always lift smoothly to avoid jerky movements that could dislodge the load.

3. Controlling the Load

As you move the load, keep it as close to the ground as possible. This helps maintain control and balance. Avoid sudden turns or movements that could make the load swing. Steady, slow movements will help you keep control and avoid accidents.

4. Lowering the Load

Do it slowly and carefully when it’s time to lower the load. Ensure the area where you place the material is clear and stable. Once the material is in position, gently release the suction by turning off the vacuum. Double-check that the load is fully released before moving the lifter.

Explore TSC's Wide Range of Glass Lifters

At Tait Sales & Consulting (TSC), we offer a variety of high-quality glass lifters that easily handle heavy and fragile materials. Our lifters are built for safety and efficiency, making lifting jobs smoother and quicker. Whether you're working with large glass panels or other heavy materials, our range of lifters will meet your needs.

Ready to upgrade your lifting tools? Explore our selection of reliable and durable glass lifters for your projects.

FAQs

How often should I check my vacuum lifter for maintenance?

Regular checks should be done before each use, and full maintenance should be scheduled every few months, depending on usage.

Can vacuum lifters be used outdoors?

Yes, but ensure the suction cups are dry and clean, and the material surface is smooth for the best grip.

What materials can vacuum lifters handle?

They are great for lifting glass, stone, metal sheets, and other smooth, heavy materials.

Is operator training required for vacuum lifters?

Yes, basic training is necessary to ensure safe and proper use.

Can vacuum lifters handle uneven surfaces?

They work best on smooth, flat surfaces. Special attachments may be needed for uneven surfaces.

Robert Tait

Robert Tait is a senior sales and operations leader with over 30 years of experience in manufacturing and distribution. Based in Overland Park, Kansas, he is the President of Tait Sales & Consulting LLC (TSC), a family-owned and operated venture he founded in 2019. TSC was founded to provide diamond tooling, material handling, and all related consumables to the natural stone industry. The industries have now expanded to include, construction, glass, tile, masonry, hardscape and concrete industries.